|

| March 02, 2021 | Volume 17 Issue 09 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

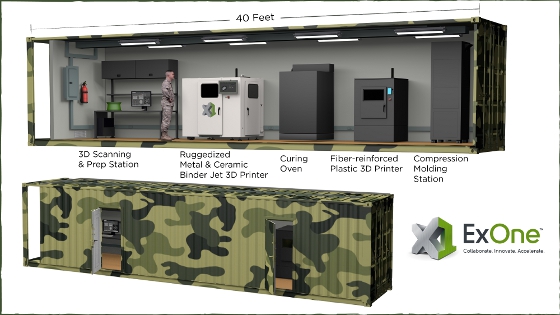

Shipping container 3D-printing factory being developed for Department of Defense

Industrial sand and metal 3D-printer maker The ExOne Company (ExOne) has been awarded a U.S. Department of Defense contract to develop a fully operational, self-contained 3D-printing "factory" housed in a shipping container.

The rugged factory pod will be set up in a standard shipping container up to 40 ft long and be deployed directly in the field, via land, sea, or air, to manufacture parts to support war theaters, disaster relief, or other remote operations.

ExOne's binder jet 3D printing transforms powdered materials -- metal, sand, or ceramic -- into highly dense and functional precision parts at high speeds. An industrial printhead selectively deposits a binder into a bed of powder particles, creating a solid part one thin layer at a time, similar to printing on sheets of paper. The technology is viewed as a desirable and sustainable production method, largely because of its high speed, low waste and cost, as well as its material flexibility. ExOne has qualified more than 20 metal, ceramic, and composite materials for its patented binder jetting process.

Awarded by the Defense Logistics Agency (DLA) last August, the $1.6-million contract will focus specifically on improving the ruggedness of ExOne's commercially available binder jet 3D printers for a wide range of operating conditions while maintaining exacting final part quality. Additionally, the project will aim to simplify use of the technology in the field with software and training, so the pod can be used with minimal technical knowledge.

"Binder jet 3D printing is a critical manufacturing technology for military use because of its speed, flexibility of materials, and ease of use," said John Hartner, ExOne's CEO.

As part of the project, ExOne is developing a special military-edition 3D printer that is capable of binder jet 3D printing more than 20 metal, ceramic, and other powder materials into direct final products or tooling. The upgraded commercial 3D printer will have a unique body style and other features that will make it a rugged, military-grade product.

By enabling a military team on-site to 3D print parts as needed, the downtime in a crisis could be reduced from weeks or months to only a few days or less, while also reducing military costs.

Ideally, military personnel would 3D print a digital file of a broken or damaged part and have a finished product in less than 48 hours without conventional tooling in the self-contained pod. This approach would save critical time (machined tooling to create parts typically takes 4 to 6 weeks), while also reducing waste and the need to carry expensive inventory in crisis zones.

VIDEO: What is metal binder jetting? [Credit: ExOne]

A digital library of parts for 3D printing can be stored electronically, as opposed to racks of spare parts in a storage depot. When a digital file is not available for older parts, the item can be 3D scanned and printed in the field. Parts to solve unique problems in the field could also be designed digitally and 3D printed as needed.

To speed development of the rugged 3D-printing mobile factory, ExOne will collaborate with several partners with unique engineering expertise on the project, including Dynovas (which specializes in materials engineering, composites manufacturing, and DoD weapons systems) and Applied Composites - San Diego (AC-SD), a leading provider of complex composite components, assemblies, engineering, and tooling to the aerospace, defense, and space systems markets. AC-SD's Reinforced Additively Manufactured Compression Assisted Molding (RAMCAM) system is an enabler to the current pod project.

Source: The ExOne Company

Published March 2021

Rate this article

View our terms of use and privacy policy